Designing sheet metal fabrications

Components made of sheet metal are very common; bracketry, electrical enclosure boxes, appliance covers and storage units to name but a few. While the design of a sheet metal component may look simple to some, a good sheet metal part should have the least possible folds, minimal deformation, look cosmetically sound and be dimensionally accurate. All of these characteristics need to be addressed during the design process.

Adding features to sheet metal parts

It's not always the case that the sheet metal part requires much thought during the design process. A simple sheet metal item will have few features, for example, a basic L-shaped bracket. Other sheet metal parts are very complex and have multiple bends, pressings, studs, pivots and may require cosmetic finishing. All these features have a function that needs to be thought about carefully, usually alongside corresponding parts. We can design sheet metal parts with all manner of features and produce industry-standard data and drawings to ensure sheet metal parts are made correctly.

Putting studs, pins and fasteners into sheet metal

We have extensive experience with sheet metal fabrications incorporating press/push-fit and welded fasteners. Understanding the options available can often simplify the design, which ultimately reduces the cost of the component.

Adding pressed features into sheet metal

It is also possible to add pressed features into sheet metal to aid stiffness and to assist with locating other parts. Pressed features are usually more common in parts made in volume as sometimes special press tools are needed to create the features. Some pressed features are standard, and sheet metal fabricators will often have different standard press tools available. Deciding which press tools to use depends on the application and the anticipated volume of parts.

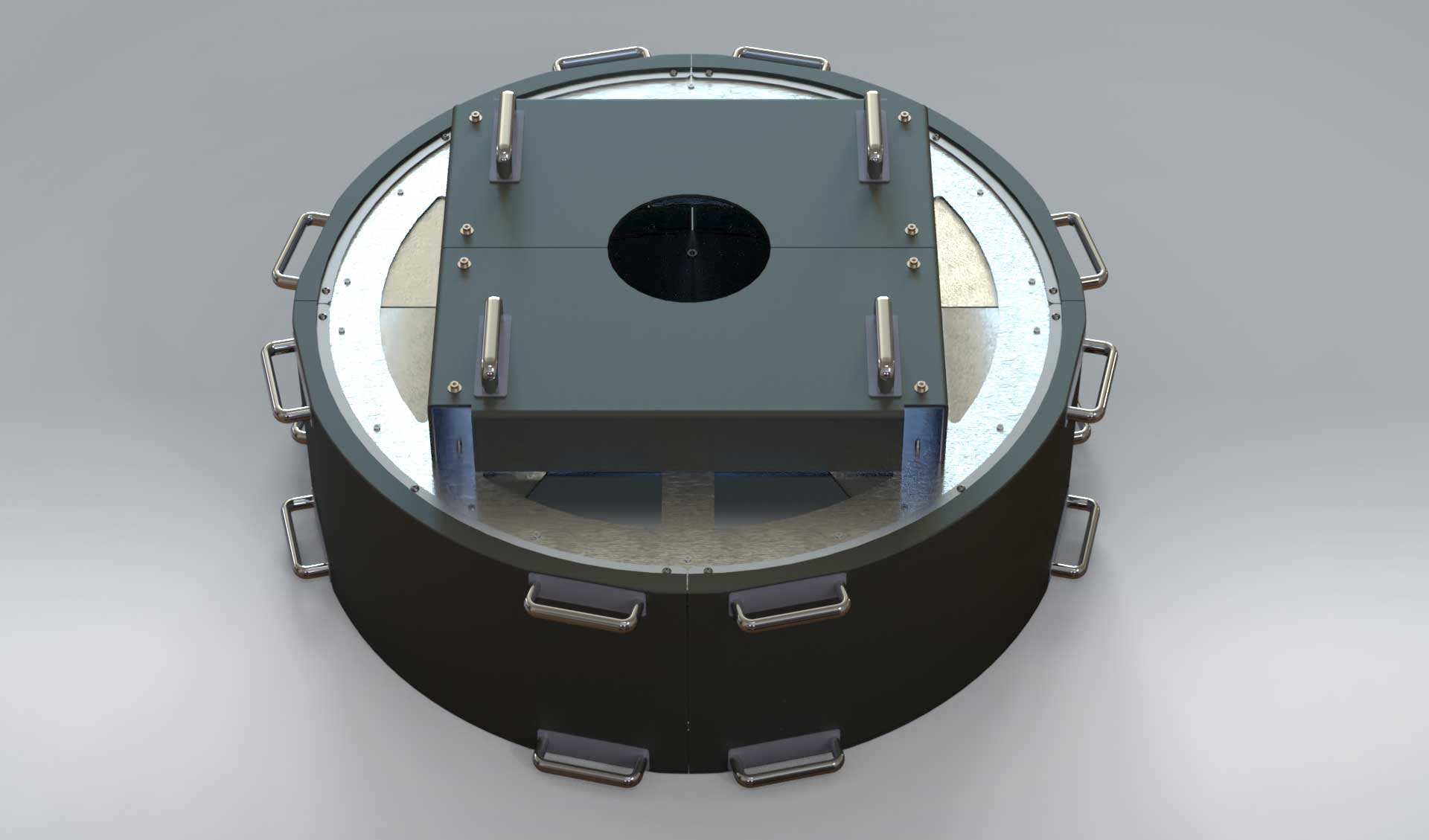

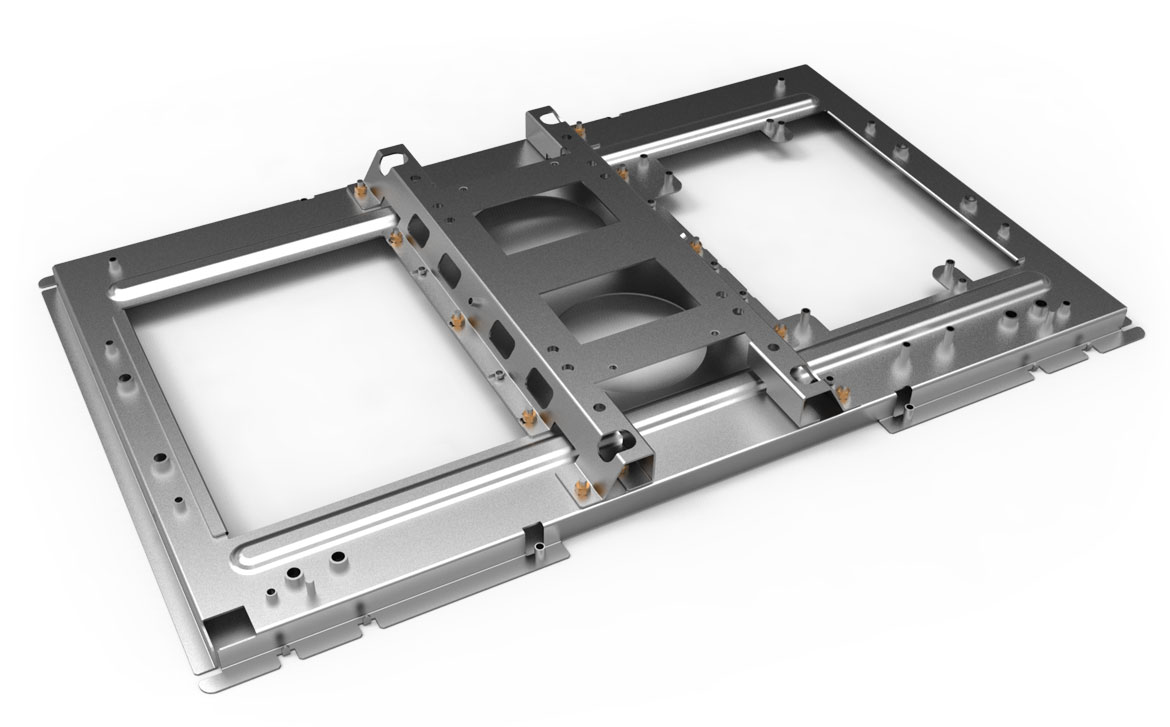

This is a sheet metal fabrication we designed for a display chassis. The production volumes were estimated around one thousand units a year so the design had to utilise standard fabrication techniques where possible, eliminating non-standard press tools. There are two main sheets welded together to provide stiffness where it's required. The design allowed for fabrication of single units for prototyping without requiring any tooling. Designs like this are perfect for testing and development work before refining them for higher volume production.

Large structural items made of sheet metal

Sheet metal comes in a huge variety of thickness from just a few microns thick to several cm’s. Larger structural items that handle heavy loads can be fabricated from sheet stock and welded or forged. We’ve worked on the design of many large structural items and have the capability to perform simple structural analysis to ensure failures are minimised.

Adding finishes to sheet metal

Sheet metal can be finished in many different ways. Some sheets are manufactured with special coatings or finishes before they are supplied to the fabricators. Other sheets are supplied raw and may require finishing like powder coating, painting, spraying or electroplating. We have a great deal of experience with different finishes, understanding their uses and limitations. We have also applied some finishes ourselves, in-house, particularly where items might be used as prototypes.

Chemically etched sheets

Thin sheets of metal can be chemically etched to produce very accurate features, and profiles, far higher than those of a laser-cut part. Chemical etching is suited to very thin metals and for products that require precision. Usually, a 'photo master' etch screen is produced and used as a screen for a particular sheet size. The disadvantage of this is that if a change needs to be made, a new etching screen would need to be produced at cost. Chemical etching is suited to final designs and is suitable for low to high volumes.

A small chemically etched sheet for precision assemblies

If your project requires sheet metal design, we can help you with a solution. Get in touch with us today to find out more about our sheet metal fabrication design service.