Exploring concepts through industrial design

An idea means nothing on its own. Ideas need exploration and nurturing. Exploring an idea determines how viable a product could be. Some ideas stem from unexpected moments of inspiration and others are created through a collective effort. We can explore your idea in a variety of ways.

Will my product idea work?

Ideas illustrate how creative our minds are. They create opportunities for improvements. Industrial design is all about exploring an idea for commercial feasibility. Not all ideas have enough commercial merit, but without some exploration, it's difficult to know.

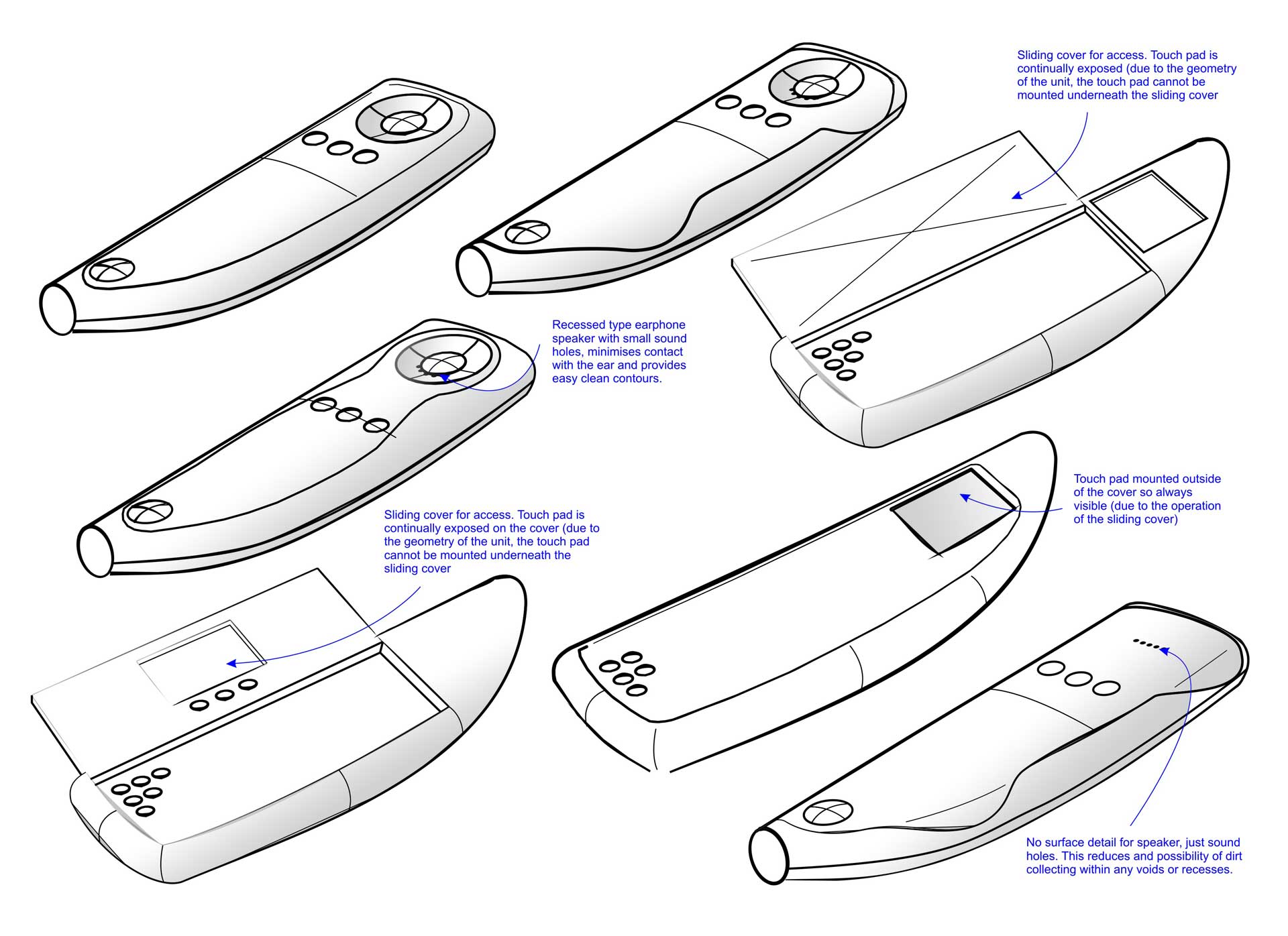

The initial stages of concept exploration usually involve understanding how a product could work and interact with its users and the environment. Exploring an idea may involve creating lots of sketches or understanding the market better. It may involve producing a first draft of a product specification or running some trials or tests.

In a lot of cases, simple models of products can be made to evaluate aspects of a design like form and useability. Simple models can be produced in various ways, using a range of materials and processes. Some models are very intricate and detailed, and others are extremely simple. In any case, exploring a concept requires some understanding of what the product is and what it's is required to do. We have a range of in-house tools and equipment to assist us with concept exploration, and we can also use external facilities if necessary.

Concept evolution & development

Concepts will inevitably evolve as they are explored. Often, aspects that were not considered or even related will begin to surface and the design direction can change very quickly. The evolution of a concept eventually leads to the foundation of a commercially viable product and enables a solid design specification to be finalised. This is then used to design and engineer a product in detail.

Methods of product development

The quick and often 'nasty' way

While the title here might provide negative connotations, some products are well suited to a simplistic design process that often involves little or no prototyping. We don't particularly like this approach, but it has been adopted on occasion under the direction of our clients. This approach can work with items that have little or no aesthetic function, or they are simply very minor modifications of something that already exists and needs improvement. In any case, we always advise against the quick and 'nasty' route but we are flexible enough to accommodate it if the alternative isn't viable. A lot of start-up enterprises and companies that are not familiar with the industrial design process often believe that a quick and 'nasty' approach to product development is the best way forward, particularly where economics is the biggest factor.

A well thought out detailed design

We cannot stress the importance of a thorough design process for a successful product. A thorough design process will involve several stages starting from the production of a detailed product specification that outlines as much of the product and its expectations as possible. This is followed by concept exploration, which may involve the production of several prototypes. The detailed design route then follows before final working prototypes are manufactured. Only then is design data produced for the manufacture of parts.