Mechanical component design

Putting the detail into your design

Most products are made up of one or more components. Each component will need to be manufactured and the process used will depend on the components' application and specification. At Design Innov8, we have a vast experience of designing components for the most common low to high volume manufacturing processes including plastic and GRP mouldings, castings, extrusions, fabrications and machined components. We understanding the limitations of each process but also work alongside suppliers to push process boundaries to produce innovative solutions. We have close links with national and international suppliers and toolmakers specialising in a range of production processes including established companies in China, Singapore and the US.

Putting it all together

We work with assemblies of various complexity ranging from a couple of parts to several thousand. We can design your complete product, addressing each component individually and ensuring that all components fit and function together. During the development process and where possible, we will work alongside your assembly lines to assemble products and test them ensuring the product assembly is as efficient as it can be. We have spent a great deal of time with various factories working through assembly flow lines to ensure products are assembled correctly and efficiently. It is also a fairly common request for us to produce assembly documentation and images.

Let us design it for you

We can take a concept and develop it into a fully working, commercially viable product.

Contact us today to find out more.

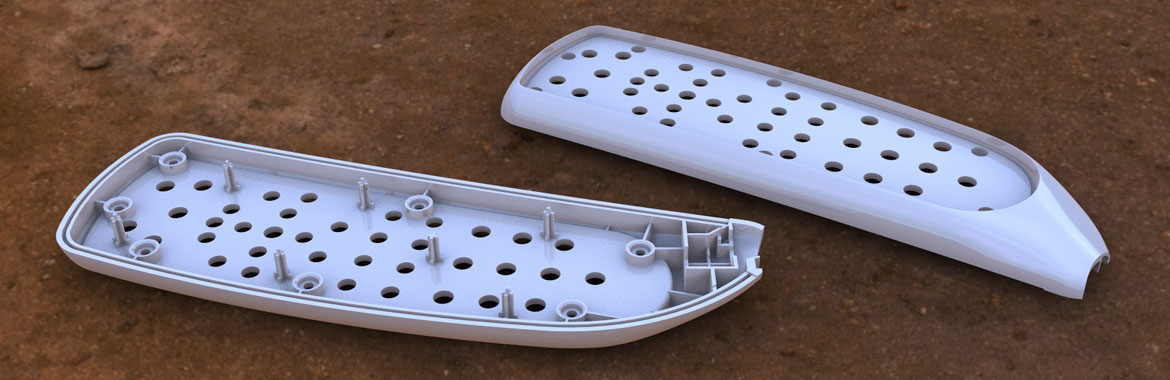

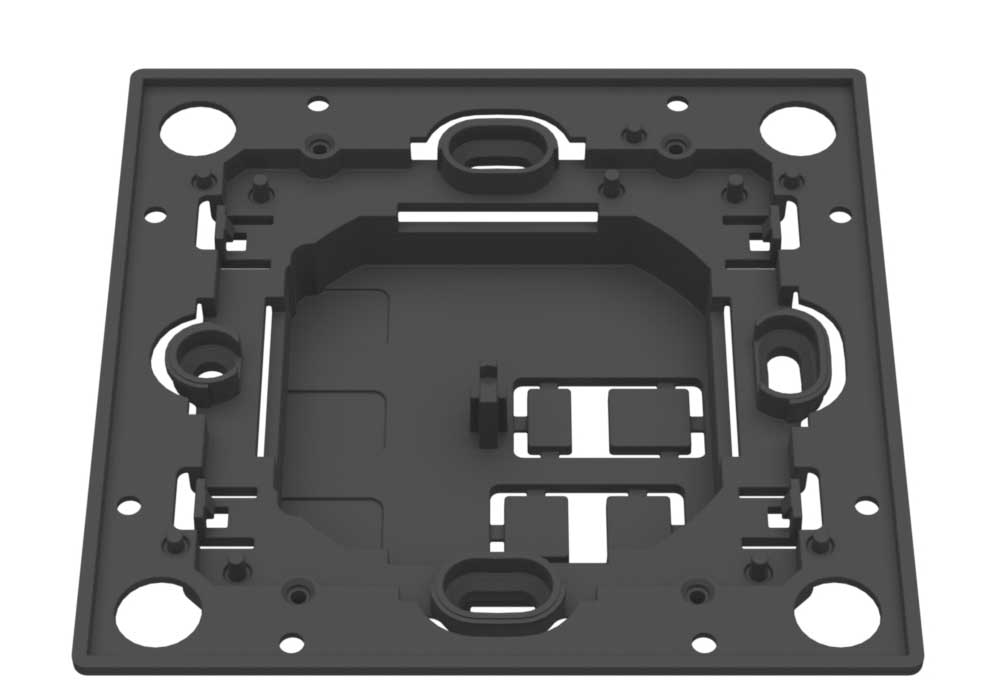

Plastic moulding design

We have extensive experience of both low and high volume plastic component design using production methods including vacuum casting, vacuum forming, rotational moulding, injection moulding, blow moulding and extrusion. From micro-moulded components to large glass-reinforced doors, we have the tools and experience to design your items with efficiency and accuracy. We have worked with all common moulding plastics and reinforced materials including ABS, PC, TPS, PET, PETG, PVC, PP, PS, HIPS and other medical grades.

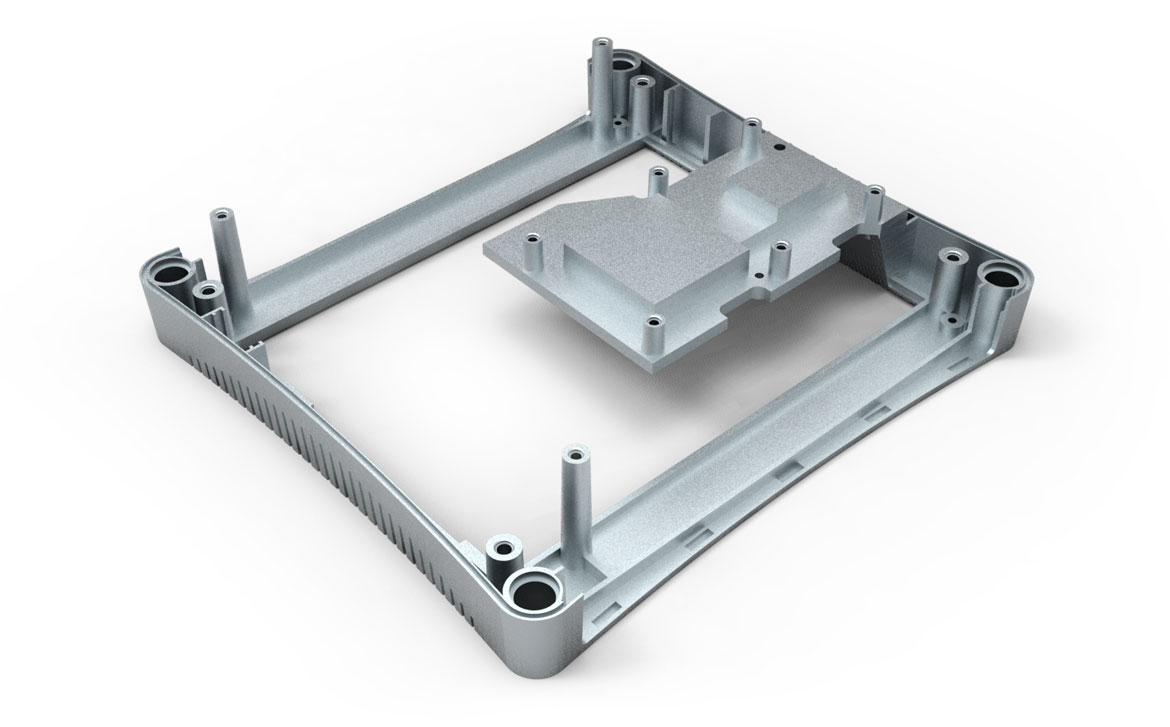

Metal casting design

There are several casting processes depending on the component, its application and quantity of manufacture. Metal castings can be produced for small production runs with minimal tooling investment. We have experience designing components for manufacture through sand casting, investment/lost-wax casting and pressure die-casting. Our recommended suppliers have extensive experience of casting manufacture and have produced castings for a range of industries including automotive, aerospace and industrial.

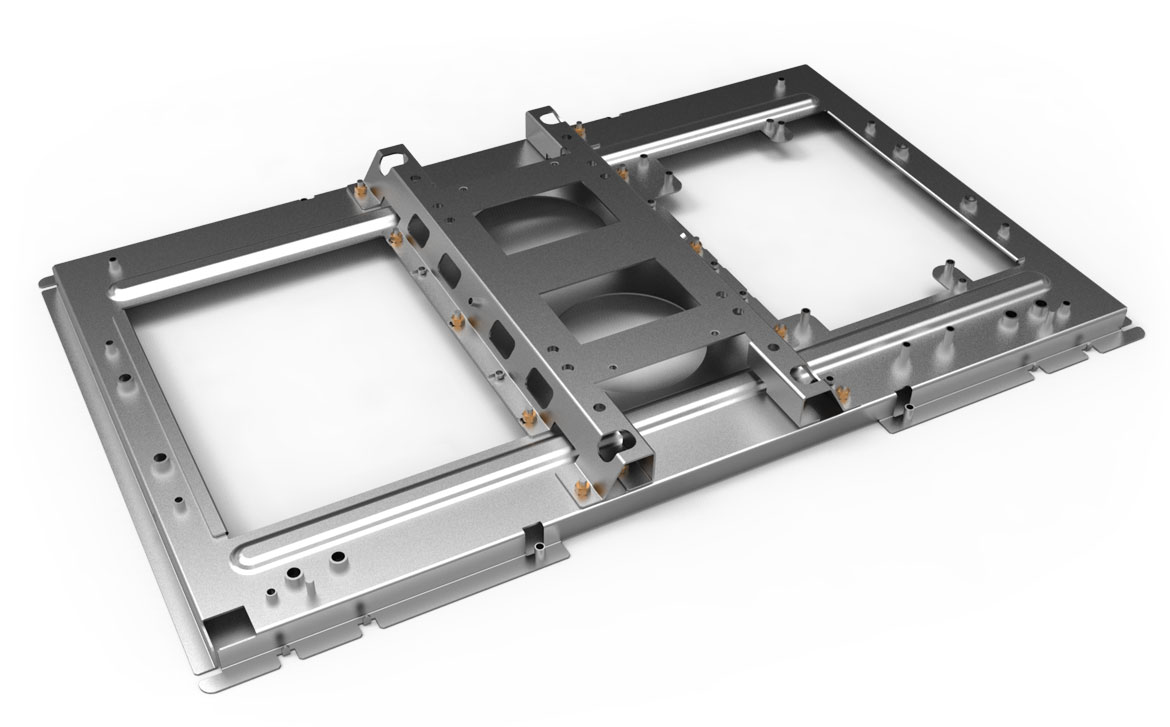

Sheet metal fabrications

From very thin sheet material down to 0.1mm to heavy duty materials thicker than 10mm, we have experience in the design and integration of sheet metal items and fabrications in aluminium, brass, steel and stainless steel sheet. We have good links to sheet metal suppliers here in the UK for fast prototype manufacture and also competitive sheet metal suppliers around Europe for larger volumes. We are also happy to work with your supplier recommendations.

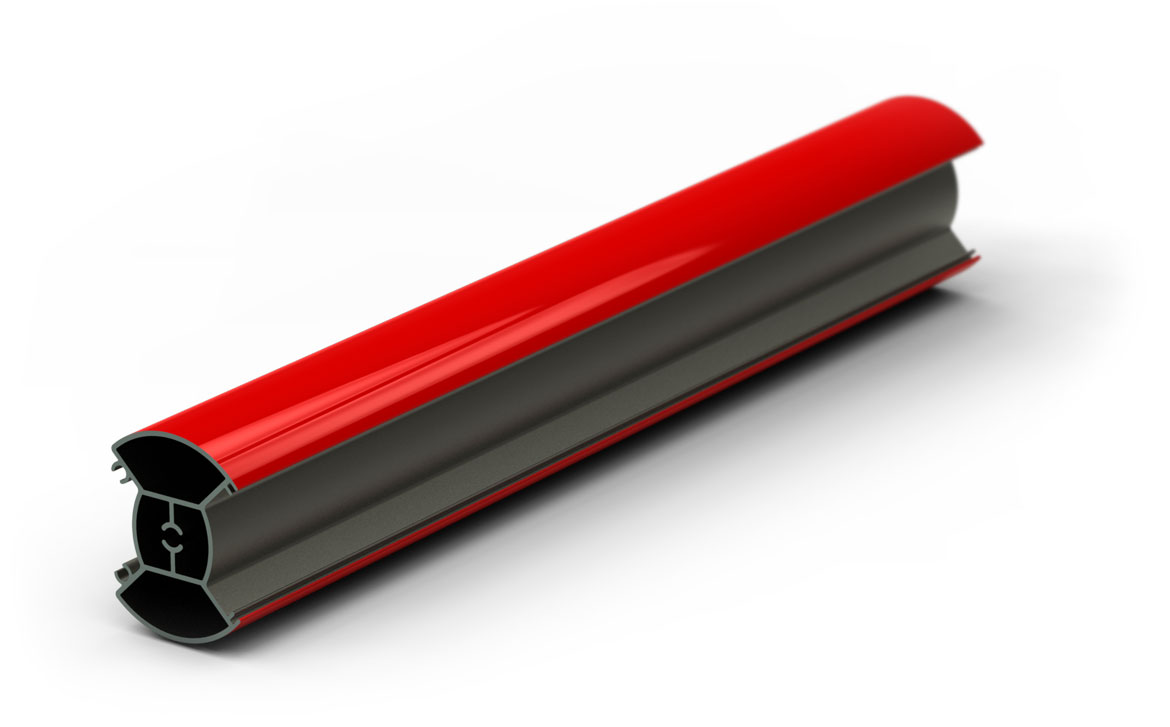

Extrusions

Extrusions are used where a design needs a fixed cross-sectional profile such as frameworks and rails. We have extensive experience designing extrusions for modular use including the integration of fixing points to make assembly easier and machining detail where necessary.

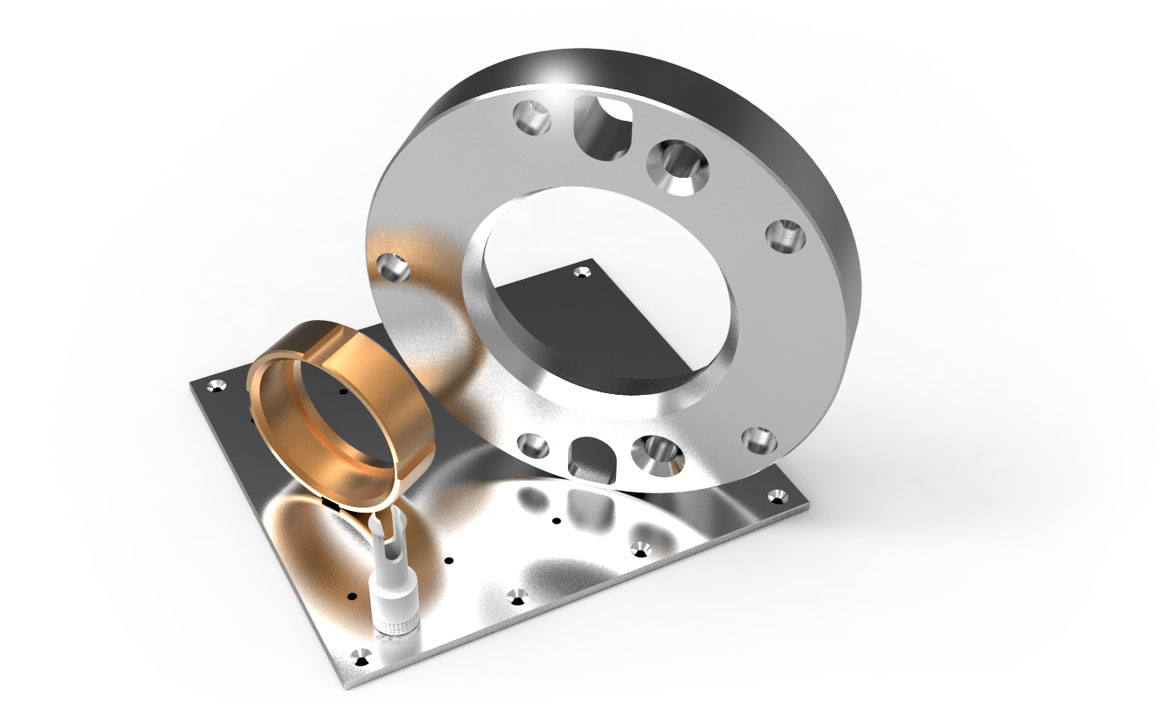

Machined components

Machined components are generally used where precision is critical and where other production processes can't produce the same accuracy and geometry. From small turned components less than 2mm in diameter to large tool beds, we can design and supply components for CNC machining. We have numerous suppliers equipped with state of the art CNC machines that can work in a variety of materials including nylon, POM/acetal, aluminium, brass, steel and stainless steel.